Transmission and BearingsUniversal joints

Manufactured according to DIN standards, these universal joints meet the strictest requirements of industrial sectors such as automotive, military, energy and machine tools. Their design guarantees high manufacturing quality, optimal strength, and a rigorous selection of steels.

The simple universal joint transmits rotational motion between two intersecting shafts forming a greater or lesser angle. It consists of two yokes and a crosshead or ball joint.

Using a simple universal joint between two intersecting shafts results in a variation in the rotational speed of the driven shaft. This irregularity in angular velocity increases with the angle between the two shafts. During one revolution, the drive shaft accelerates and slows down the driven shaft twice.

Simple universal joints mounted alone are therefore suitable when these speed fluctuations do not pose a problem. To achieve a constant velocity connection and eliminate these irregularities, two single universal joints connected by an intermediate shaft can be used, or, more economically, a double universal joint.

Universal joints are available with four hub types:

- Solid: without a machined hole.

- Bored: with a round, hexagonal, or square hole.

- Splined: with longitudinal grooves inside the bore.

- Keyed: with a keyway to prevent rotation of the universal joint on the shaft.

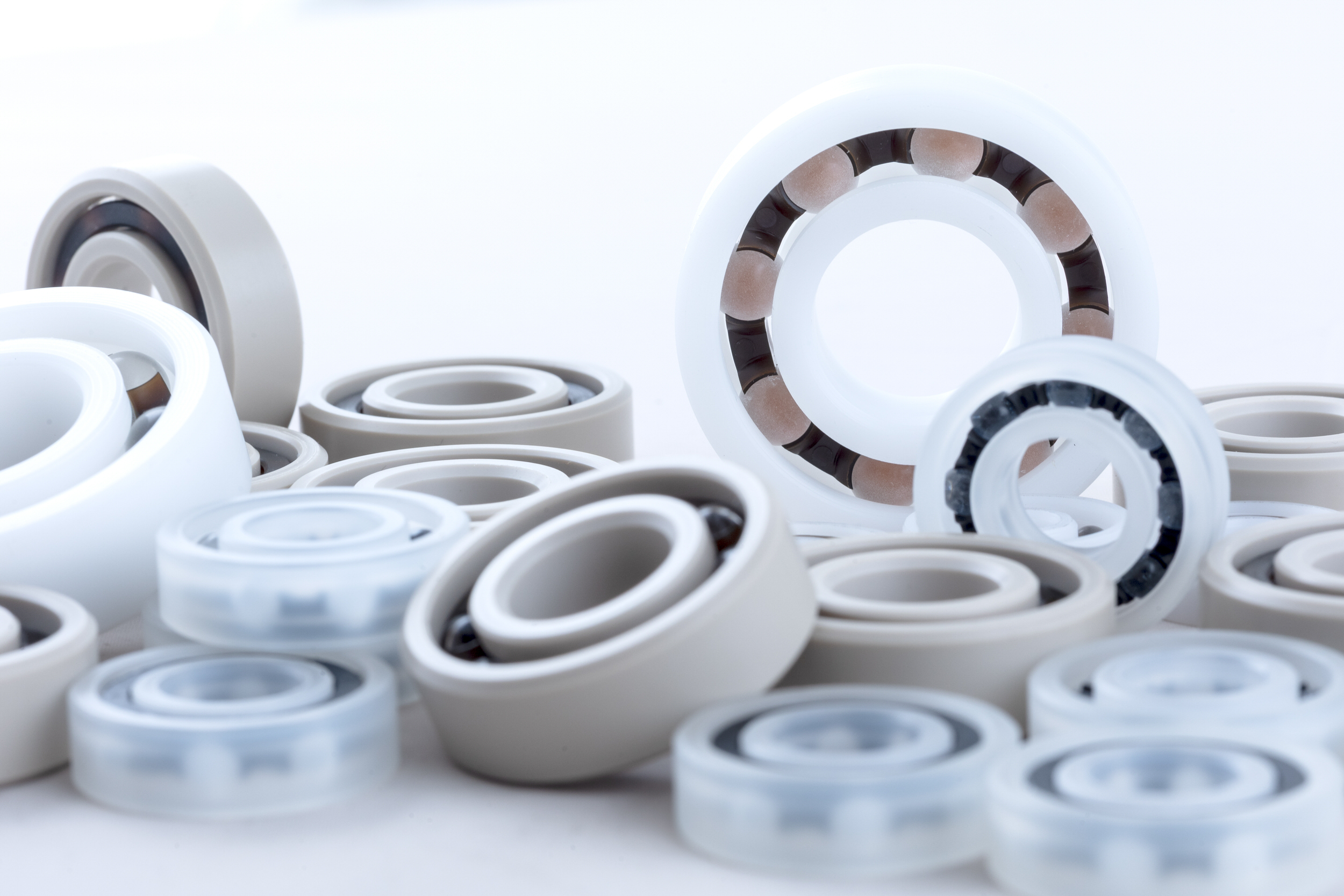

Bearing universal joints are available in two types:

- Sliding bearings: Suitable for low-speed applications, they withstand shock loads, reversals, rough operation, and high torques.

- Needle bearings: Designed for high rotational speeds, low torques, and large angles.