Mining operations require grinding media or grinding balls for crushing minerals or rock extracts in order to seperate them and obtain pure powders.

Crushing is done by contact between the grinding balls and the minerals which are placed together inside big mixing containers : the grinding balls crush the raw ore thanks to their weight and energy created by the rotating speed inside the mixers.

Grinding balls : 40 to 120 mm

We offer grinding media in steel, in order to meet the requirements of this activity.

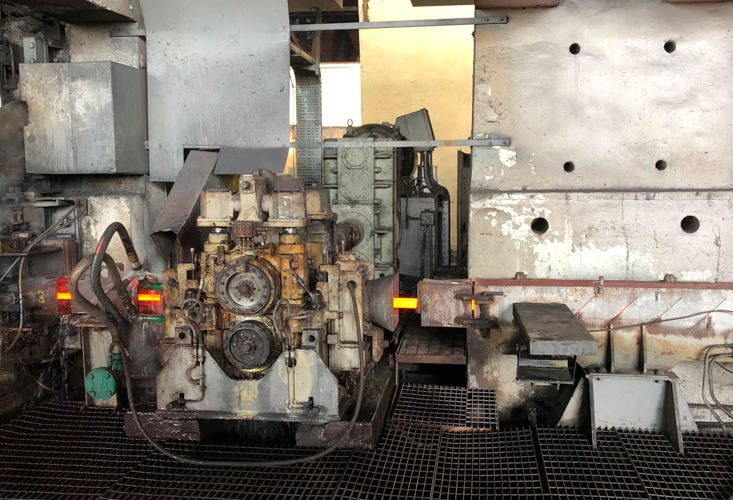

The production process from steel material to the production of grinding media is carried out in the same location.

This enables us to optimize production costs, reduce transport costs while maintaning full control of the production line (foundry, forging, hardening, grinding).

Our high quality is very stable and fully meets international standards.

Investigation on our balls to make material or hardness controls

Different production steps :

Stock and logistic solutions :

We have regular stocks of grinding balls in diameters 40, 60, 65, 80, 100 and 120 mm. Testing is carried out on each production batch as follows : on surface hardness and core hardness in order to check the balls with respect to the grinding application.

We can manage full or partiel container logistic in order to supply your mining locations or closest ports of delivery.

Material Composition (current % values)

| C |

Mn |

Si |

S |

P |

Cr |

Ni |

Cu |

|

| 0,52-0,6 |

0,5-0,8 |

0,17-0,37 |

0,04 |

0,035 |

0,25 |

0,3 |

0,3 |

Grinding balls : 40 to 120 mm

Grinding balls : 40 to 120 mm

Investigation on our balls to make material or hardness controls

Investigation on our balls to make material or hardness controls