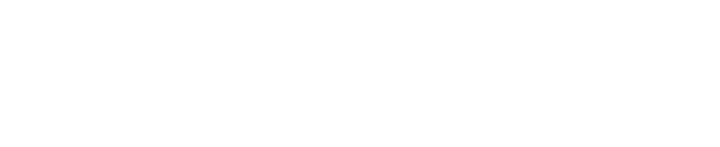

Balls > Precision et QualityChecks

Inspections are performed throughout production to maintain quality control at all times.

These inspections are performed by both the production team and the quality team; they ensure the quality of our precision balls.

Here are some of the inspections we perform:

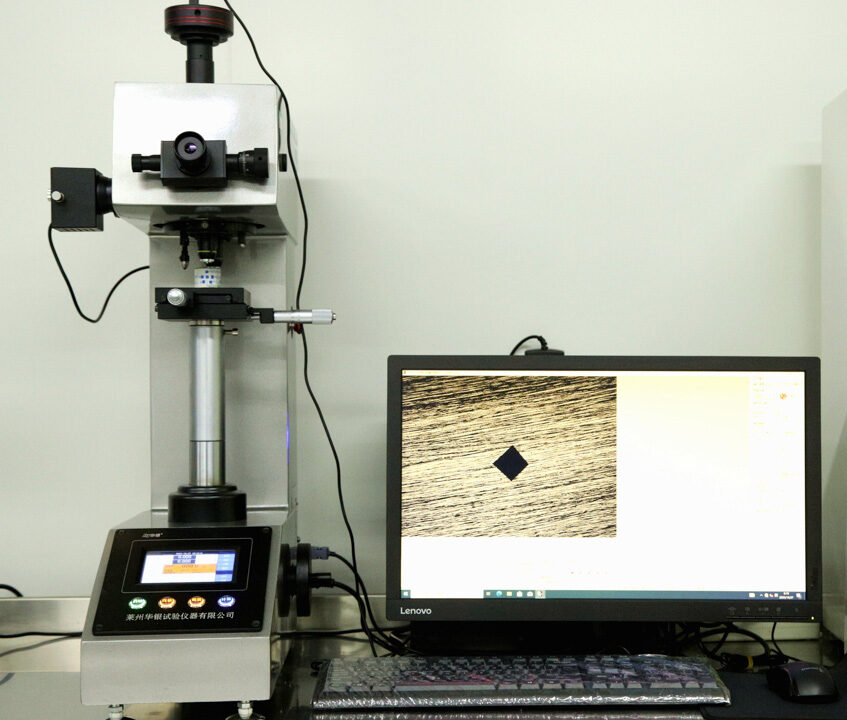

- Hardness

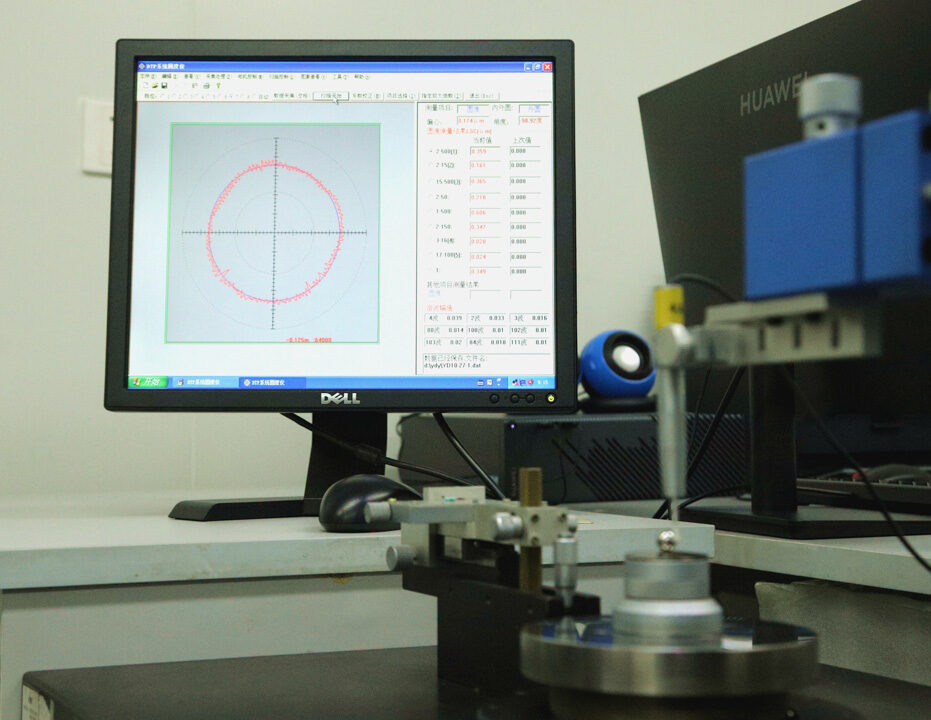

- Sphericity

- Dimensional tolerances

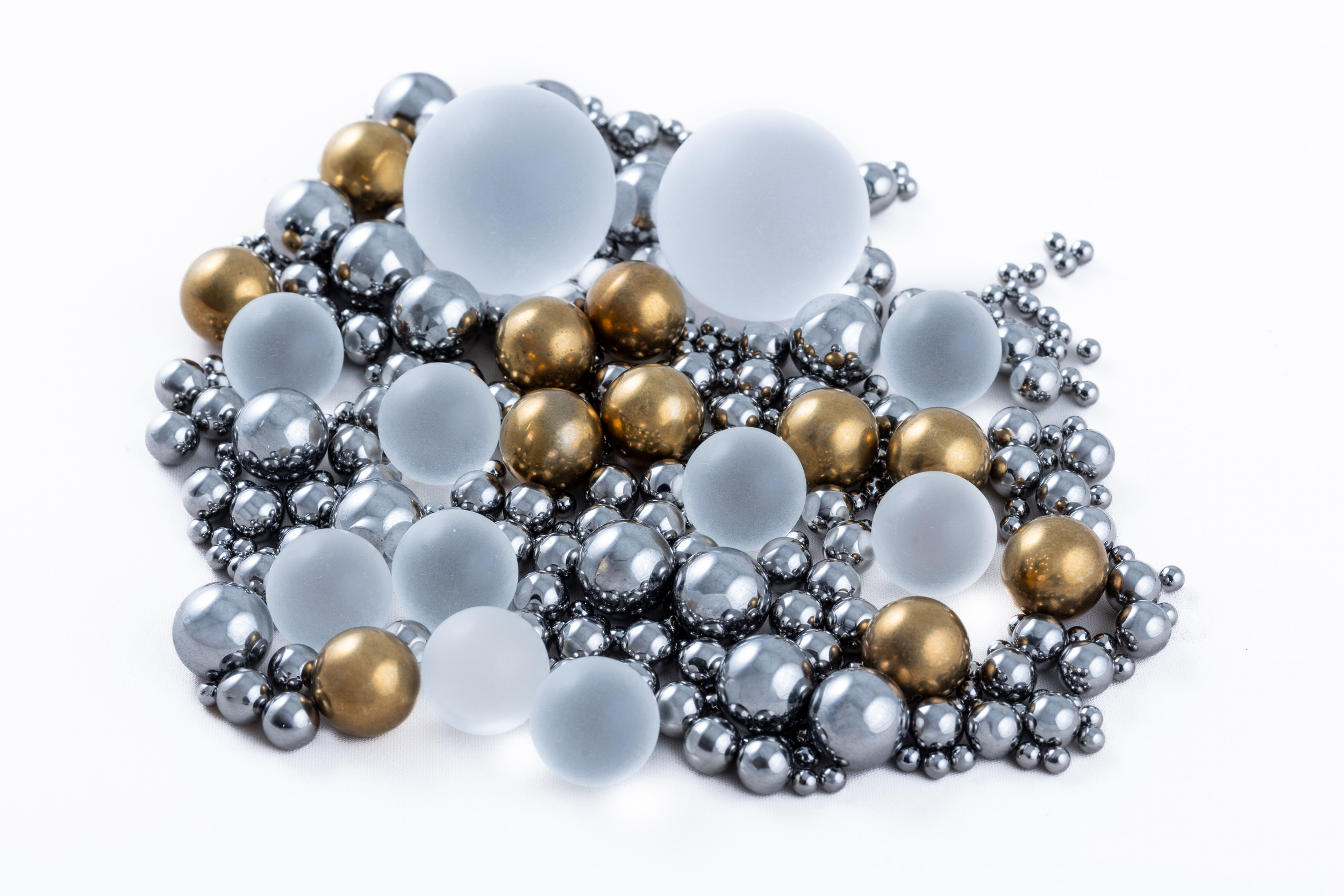

- Roughness

The CIMAP Group can perform the following measurements and tests in the field of balls and rollers:

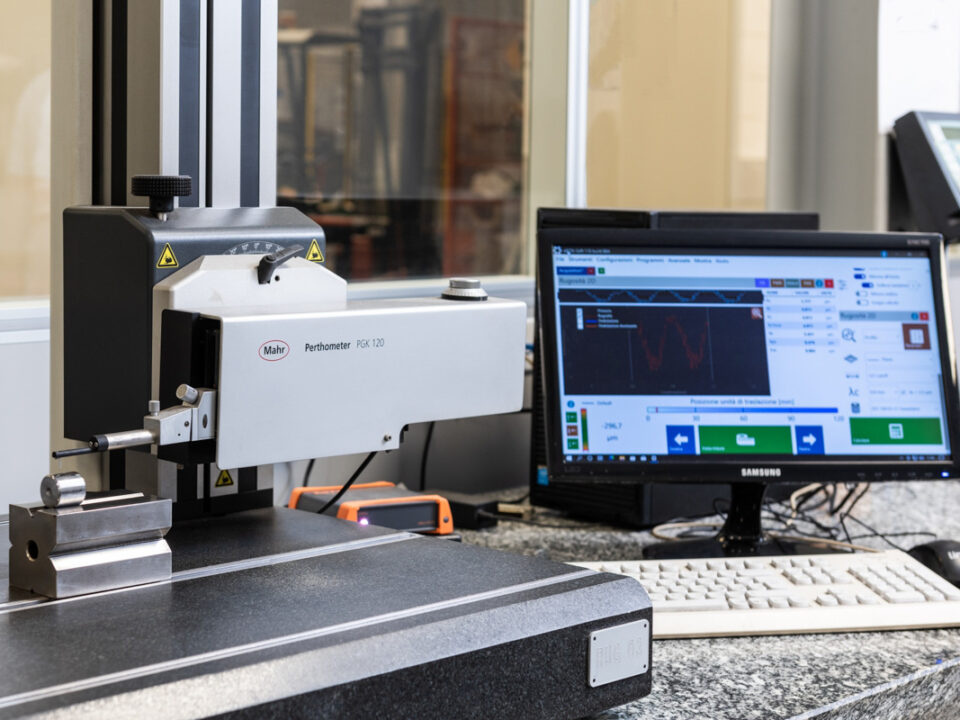

Dimensional and hardness testing

- Diameter measurement with an accuracy of 0.1 micron

- Sphericity and circularity control

- Hardness measurement (HV and Rockwell)

Specific analyses and inspections

- Metallographic analysis

- Detection of microcracks by eddy current testing

- Ball sorting by diameter using roller sorting machines

- Automatic multi-station, multifunction sorting machine for large rollers

- Surface inclusion cleanliness inspection (quantitative and qualitative)

- Surface content control of calcium, manganese, or iron to limit these contaminants in specific applications

- Ultraclean washing of parts with distilled ultrapure water for medical and pharmaceutical applications

Perfect knowledge

CIMAP has a thorough understanding of all these factors, making our role particularly important for our clients and prospects:

Define and support their projects,

Advise them and propose quality and/or material improvements at all times,

Consistently deliver top-notch quality.